Your waste water is no longer a waste!

“We are a trusted name in the industry with its remarkable presence since 2014 for water solutions.”

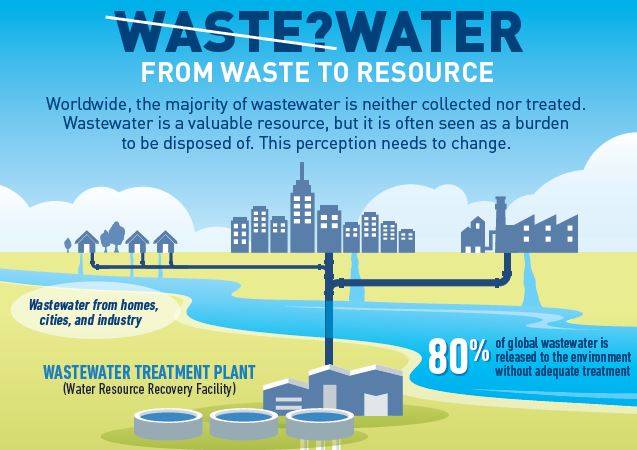

As all of you know water is the most precious natural resources and it deserves to be handled with care. In order to protect the planet, it is important to stop water pollution and treat the wastewater and remove all its contaminants. Well, the list is never-ending. We should know why government and big organizations have to come forward and start building more water treatment plants in every possible place.

With an increasing population, urbanisation, and industrialization, India has extremely water-stressed regions and a failure to effectively manage its water resources. As a result, efficient and cost-effective biological treatment and reuse of industrial wastewater has emerged as a viable option for meeting future water demands. The content of effluents may differ depending on the type of industrial business. Ammonia, acids, heavy metals, calcium ions, detergents, paints, organic matter, solvents, lipids, cellulose, food wastes, and other contaminants are commonly found in industrial effluent that must be treated.

Because a significant amount of industrial wastewater ends up in the environment, businesses must effectively treat effluents in order to meet the mandated criteria.

1. Wastewater from the food and beverage industries contains high levels of nutrients, organic carbon, and organic particle matter. Wastewater from dairy operations may contain high levels of fats, oils, and grease, as well as whey liquid, which must be separated and treated properly.

2. The bleaching stage in the pulp and paper industry accounts for around 85% of total effluent. Organic and inorganic components are present in variable proportions. Activated sludge treatment and aerated ponds are the most frequently used sewage treatment procedures in the paper sector.

3. Hydrocarbons, mercaptans, oil and grease, phenol, ammonia, and sulphides are only a few of the pollutants found in wastewater generated by the petroleum industry.

4. Before being discharged into the environment, the majority of hospital effluents are discharged into sewer systems or processed at an on-site sewage treatment facility. However, because it contains pharmaceutically active substances, antibiotic-resistant genes, viruses, and a high BOD and COD concentration, improper treatment of this effluent may endanger human health.

5. Chemical manufacturing wastewater contains extremely dangerous contaminants as well as organic and inorganic wastes in varying concentrations. Materials emitted can be poisonous, carcinogenic, and mutagenic, necessitating extensive treatment prior to release.

6. Pharmaceutically active chemicals with inherent biological activity may be found in wastewater from drug and pharmaceutical businesses. Without proper management, its presence in the environment can promote the growth of antibiotic-resistant bacteria, increase the toxicity of chemicals, and have a negative impact on human and aquatic health. Individual API or drug recovery, aerobic or anaerobic biological treatment, inactivation of active compounds by UV oxidation, or basic physical-chemical treatment procedures are common wastewater treatment options.

Global Envirotech is one of India's largest and most versatile waste management service providers, committed to meeting the growing environmental challenge. Global Envirotech offers environmental management solutions to the country's industrial sectors. Global Envirotech's wastewater treatment solutions have proven to be effective for sewage and industrial wastewater treatment. Our wastewater treatment systems have been specifically designed to decompose organic waste successfully and significantly, and they are aimed at a wide range of industries and municipal authorities. While improving the treatment process, Global Envirotech has the potential to significantly reduce sludge volume, operational costs, bad odour, and COD and BOD levels in industrial wastewater.